I. Introduction

For owners and fleet managers of light commercial vehicles, tire selection directly impacts operational efficiency, cost, and safety. Among the core choices, bias ply and radial tires represent two fundamental and structurally distinct types. Understanding the difference between bias ply and radial tires is crucial for making the correct decision. This knowledge is essential when selecting the right lt tyres (light truck tires) for your specific needs.

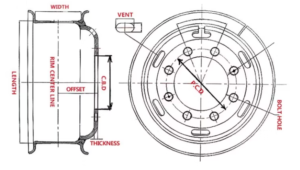

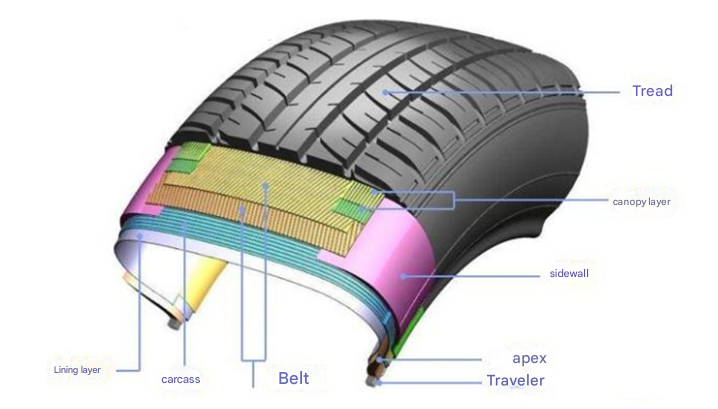

II. Core Distinction: How Carcass Structure Defines All Characteristics

All performance differences between the two stem from how their carcass cords (the tire’s skeleton) are arranged:

-

Radial Tires: The carcass cords run radially from bead to bead, at approximately a 90-degree angle to the centerline of the tread. A robust, rigid “belt” layer made of steel cords is added under the tread crown. This structure resembles the meridians on a globe, hence the name “radial”.

Bias Ply Tires: The carcass cords are arranged in a crisscross lattice pattern. Multiple layers of cord are set at an angle (typically 30-40 degrees), with adjacent layers crossing each other. The structure resembles an old-fashioned woven net.

II. Detailed Performance Comparison: Impact on Your Operation

Due to these fundamental structural differences, bias light truck tires and radial light truck tires perform very differently in real-world applications.

1. Rolling Resistance & Fuel Economy

Radial Tires: The belt layer significantly restricts circumferential tread movement, resulting in lower rolling resistance. This means the engine works less to turn the tires, leading directly to better fuel economy. This offers significant long-term savings for lt tyres used in frequent stop-start city delivery or medium-haul transport.

Bias Ply Tires: The friction between the crossing cord layers and greater circumferential deformation lead to higher rolling resistance and, consequently, higher fuel consumption.

2. Load Capacity, Cushioning & Comfort

Radial Tyre: The flexible sidewalls (due to radial cords) provide excellent radial elasticity, absorbing road shocks and bumps effectively. This offers superior ride comfort for both driver and cargo. The sturdy belt layer ensures ample load-bearing capacity.

Bias Ply Tyre: The entire carcass (including sidewalls) is stiffer, offering poorer cushioning and a more pronounced bumpy ride. However, the thick carcass is robust under standard loads.

3. Sidewall Strength & Damage Resistance

Radial Tyres: Sidewalls are relatively thinner and more flexible. This makes them more susceptible to sidewall bulges or damage from sustained scraping against curbs, sharp edges, or rough off-road terrain.

Bias Ply Tyres: Sidewalls are extremely thick and rigid, offering high lateral support. They better resist curb scuffing, rock impacts, and cuts, demonstrating greater damage resistance in complex, low-speed environments like construction sites or farm tracks.

4. Handling Stability & Wear

Radial Tire: The larger, more evenly pressurized contact patch provides strong grip. The belt stabilizes the tread, resulting in more precise steering response, better high-speed stability, and more even tread wear, typically leading to a longer service life.

Bias Ply Tire: The tread deforms more under load, leading to somewhat sluggish steering and lower high-speed stability compared to radials. Tread wear is generally faster.

5. Heat Generation & High-Speed Performance

Radial Tires: Minimal inter-ply friction and better heat dissipation mean lower heat buildup during high-speed travel, making them more suitable for sustained medium-to-high-speed operation.

Bias Ply Tires: Friction from the crossing plies generates more heat. They heat up faster at high speeds, posing a risk of heat accumulation on long highway runs, thus making them more suited for low-to-medium speed applications.

III. Selection Advice: Based on Specific Light Truck Use Cases

Prioritize Radial Light Truck Tires for:

Urban Delivery & Logistics: Where fuel economy, comfort, and low noise are priorities.

Medium-to-Long Haul Highway Transport: Requiring good high-speed stability and long mileage.

Vans requiring good handling and grip.

Consider Bias Light Truck Tires for:

Construction Sites, Agricultural Fields, Short-haul Mine Transport: Where terrain is rough and supreme sidewall protection against cuts and abrasions is needed.

Specialty vehicles frequently driving over curbs or on gravel roads.

Specific low-speed yard vehicles where tire cost is the paramount concern.

Critical Safety Reminder: Regardless of type, the same axle must be fitted with tires of identical construction, size, and tread pattern. Mixing bias ply and radial tires on an axle is strictly prohibited as it severely compromises vehicle handling stability and safety.

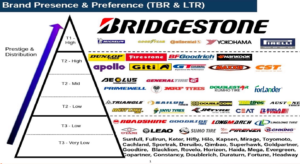

IV. Considering Brands and Value for Money

After determining the tire structure, brand choice is key to balancing performance and cost for your commercial light truck tire needs.

International Brands: Such as Michelin, Bridgestone, generally offer balanced, stable performance with long-standing reputations for wear, fuel efficiency, and safety, but at a higher price. Suitable for high-frequency, long-distance fleets with demanding uptime and mileage requirements.

Domestic Brands: Such as Zhongce, Double Coin, Linglong, Forlander, offer outstanding value for money with extensive product lines well-suited for medium/short-haul transport and diverse domestic road conditions. Purchase from authorized dealers or official channels to ensure genuine products and after-sales support.

3. Channel Verification: Be wary of unusually low-priced tires from unknown sources. Always check for complete DOT (or equivalent) certification marks on the sidewall and the manufacture date (e.g., “3623” means the 36th week of 2023). Tires with excessive shelf time (e.g., over 3 years) may have aged rubber and compromised performance.

V. Conclusion

For most modern light truck users, radial light truck tires have become the dominant and preferred choice due to their combined advantages in fuel savings, comfort, durability, and handling. Bias light truck tires retain indispensable value in harsh, low-speed applications thanks to their rugged sidewalls.

Your final choice should follow this logic: first, determine the tire structure based on primary road conditions and speed; second, select an appropriate brand tier within your budget according to your operation mode (long-haul/short-haul); finally, purchase from official channels and verify product condition. This approach ensures optimal balance between operational cost and efficiency, with safety as the foremost priority.

Forlander, as a leading tire manufacturer with extensive experience and comprehensive product portfolios including PCR, TBR, and OTR tires in various tread patterns and sizes, is committed to providing professional tire solutions. If you have any specific requirements or questions regarding lt tyres or commercial light truck tire selection, our tire experts are ready to assist.