This article introduces the structural design, construction design, and production process of Forlander LAND 701, LAND 702 raised white letter tires. We determine the position of the white letters based on user requirements or market feedback, ensuring that the raised height after grinding is between 1.5 and 2.5 mm. The white letter tires sidewall rubber should have properties such as tear resistance and resistance to cut growth, while also ensuring proper bonding and vulcanization with adjacent components. Care should be taken to protect the white sidewall from contamination during production, packaging, and transportation.

Introduction

With the development of highways in China, the advantages of radial tires have become increasingly evident. Additionally, as China joins the WTO, competition in the radial tire market has intensified, accelerating product updates and new product development. Product quality and price are key factors in competition, and the appearance of tires is becoming increasingly important. The design of performance tires with white lettering is adapting to this trend, especially for passenger vehicles where aesthetic requirements are high.

I. Raised White Letter Tires Product Design

1.1 Structural Design

The design of white letter tires, aside from the white edges and letters, is identical to that of black sidewall tires. Key considerations in the design of Forlander white letter tires include:

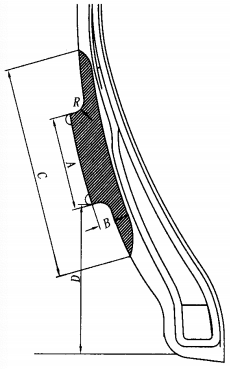

- Position and Height of White Edges and Letters

The position of the white edges and letters is determined based on user requests or market feedback. To ensure a neat finish after grinding, they must maintain a specific raised height. If too high, it wastes material and affects balance; if too low, grinding may leave black rubber, lowering visual quality. For example, the width of the white letters (logo) is designed to be 20 mm with a raised height of 3.5 mm, ensuring a final height of about 2.5 mm after grinding.

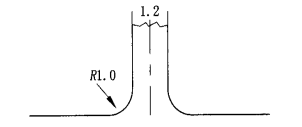

2.Ventilation Holes on Molds

No ventilation holes are placed within the actual width of the white rubber to avoid “white hairs” that can be ground off during processing. To address rubber shortage issues, ventilation lines can be set in non-grinding areas. The design of these holes should ensure smooth transitions to prevent breakage.

3. Rounded Edges of White Edges and Letters

A uniform radius of 1 mm is set at the outer edges of the white letters and edges to allow rubber to flow properly, ensuring a neat finish after grinding.

1.2 Construction Design

A material distribution diagram is created based on the positions of the white edges and letters. The position of the white letters should be near the top of the rubber core, as this area experiences less deformation. The volume and mass of the white rubber are determined from the distribution diagram to design semi-finished products.

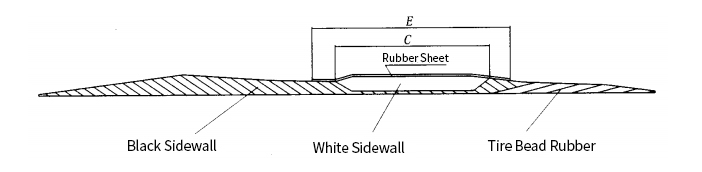

The width of the white rubber in semi-finished products should be larger than that of the finished product to prevent substances from the black rubber from migrating to the white edges and letters, causing discoloration.The width of the white rubber in semi-finished products should be larger than that of the finished product to prevent substances from the black rubber from migrating to the white edges and letters, causing discoloration.

1.3 Formulation Design

The design of the semi-finished Forlander white letter tires white sidewall includes four types of rubber: black sidewall rubber, white sidewall rubber, bead rubber, and white covering rubber:

White Sidewall Rubber

This rubber must have properties that match the curing speed of the entire tire, good bonding with adjacent components, and excellent resistance to tearing, aging, and discoloration.

Covering Rubber

Although it makes up a small percentage, its formulation is crucial for bonding with white rubber, black sidewall rubber, and bead rubber, while also providing good aging resistance.

Black Sidewall Rubber and Bead Rubber

These are designed in the same way as those for black sidewall tires.

II. Production Process

2.1 Mixing

Strict control is required to prevent contamination during mixing. Contaminated rubber compromises the appearance and quality of the final product.

2.2 Extrusion

The accuracy of the dimensions of the semi-finished sidewall is crucial and is influenced by the design of the extrusion dies. Our company, Forlander, uses advanced triple compound extruders to ensure cleanliness and prevent contamination during the process.

2.3 Molding

Forlander white edge tires are molded using a secondary molding machine, while white letter tires can be molded using either primary or secondary machines. Special attention is needed to protect the white side during molding.

2.4 Vulcanization

The vulcanization process is similar to that of black sidewall tires, requiring proper placement of the white side and ensuring that the joints are in non-visible areas.

2.5 Grinding

Grinding is a critical step where the final appearance of the Forlander white edges and letters is revealed. This process is essential for creating raised white letter tires that stand out. Special machines are used that can operate automatically or manually, ensuring uniformity in height after grinding.

Conclusion

The development and production of Forlander tyres with white writing involve several key considerations. Optimizing mold design can enhance the uniformity of the white edges. Due to the differing properties of white and black sidewall rubbers, Forlander raised white letter tires are best suited for tires rated below speed category T. The production process for Forlander white letter tires is more complex and stringent than for black sidewalls, resulting in higher costs. These best raised white letter tires combine performance with aesthetic appeal, meeting the demands of modern consumers.